Multi-fidelity Modeling

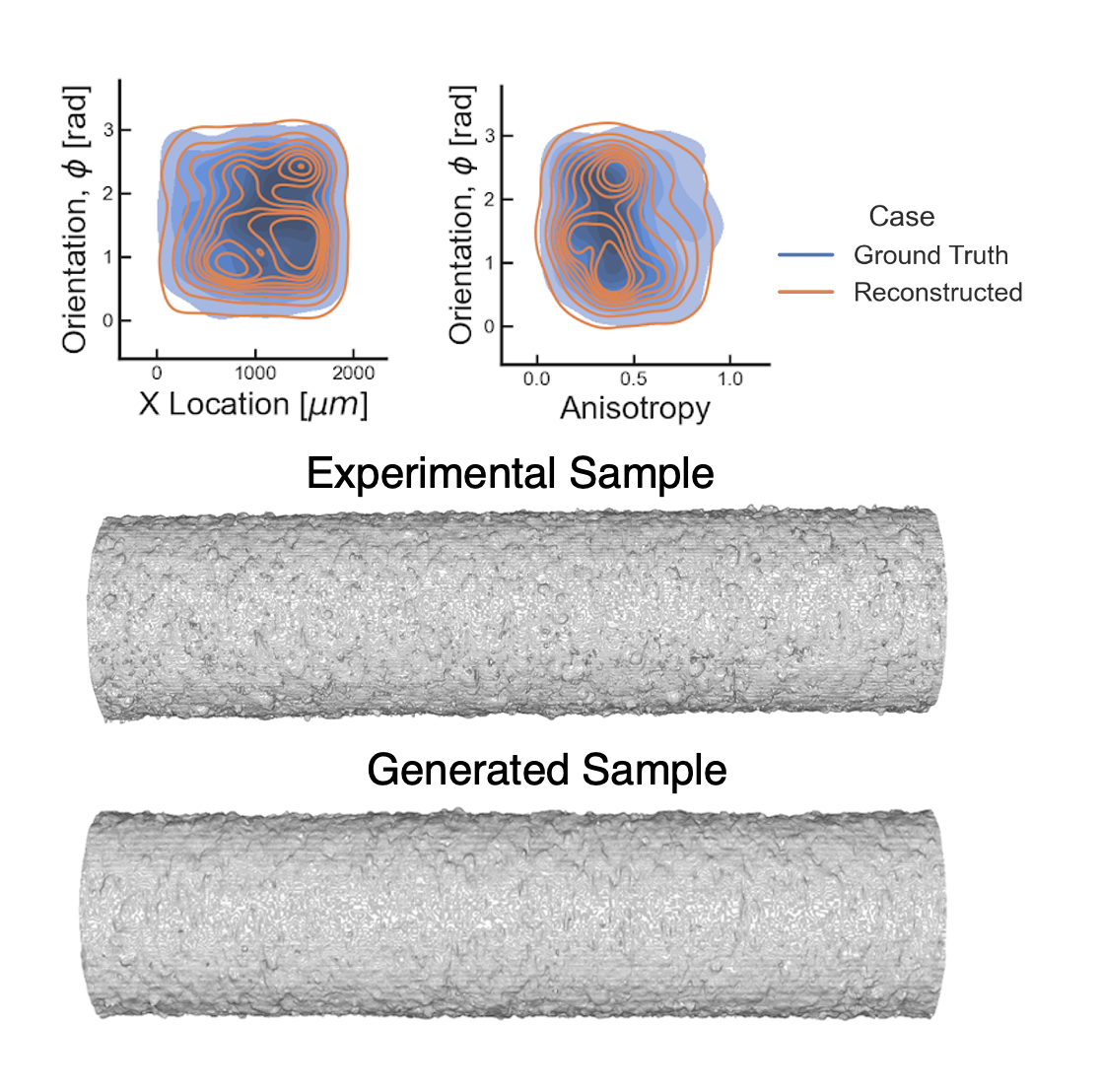

High-fidelity simulations of physical systems can take hours or days to run, making iterative design and bulk analysis impractical. We develop methods to accelerate simulation-based workflows using surrogate models, multi-fidelity approaches, and generative deep learning.

Uncertainty Quantification

Physical systems are inherently stochastic. Sensor measurements are noisy, material properties vary, and small perturbations can lead to different outcomes. We develop generative models that learn distributions rather than point estimates, characterizing uncertainty from sparse or noisy data to support more reliable prediction and control.

Foundation Models for Engineering

Labeled data is scarce in engineering domains. Generating training labels often requires expensive experiments or time-consuming simulations, limiting how much supervision is available. We develop self-supervised and pre-trained models that learn useful representations from unlabeled data like sensor streams, simulation outputs, and geometric descriptions. These models can then be fine-tuned for specific downstream tasks with minimal labeled examples.